UNLOCK THE POTENTIAL OF THE DIAMAGNETIC MICRO FACTORY*

Pelrine Innovations is a research, design and development company focused on innovative automation using novel materials and new technologies. We believe that cutting edge technologies and novel materials can reinvent the world. We also believe that the value of a technology lies in its practical application and its ability to foster new and diverse development…which is why we are pleased to introduce the Diamagnetic Micro Factory…a platform designed to transform automation.

The diamagnetic micro factory system is a platform technology that can support applications across a range of industries as well as non-manufacturing processes. Through Pelrine Innovations, you can purchase a working beta level diamagnetic micro factory platform, activate your system, and customize it to meet your unique business and research needs. Join a community of like-minded researchers and developers focused on paradigm shifting solutions to business operations.

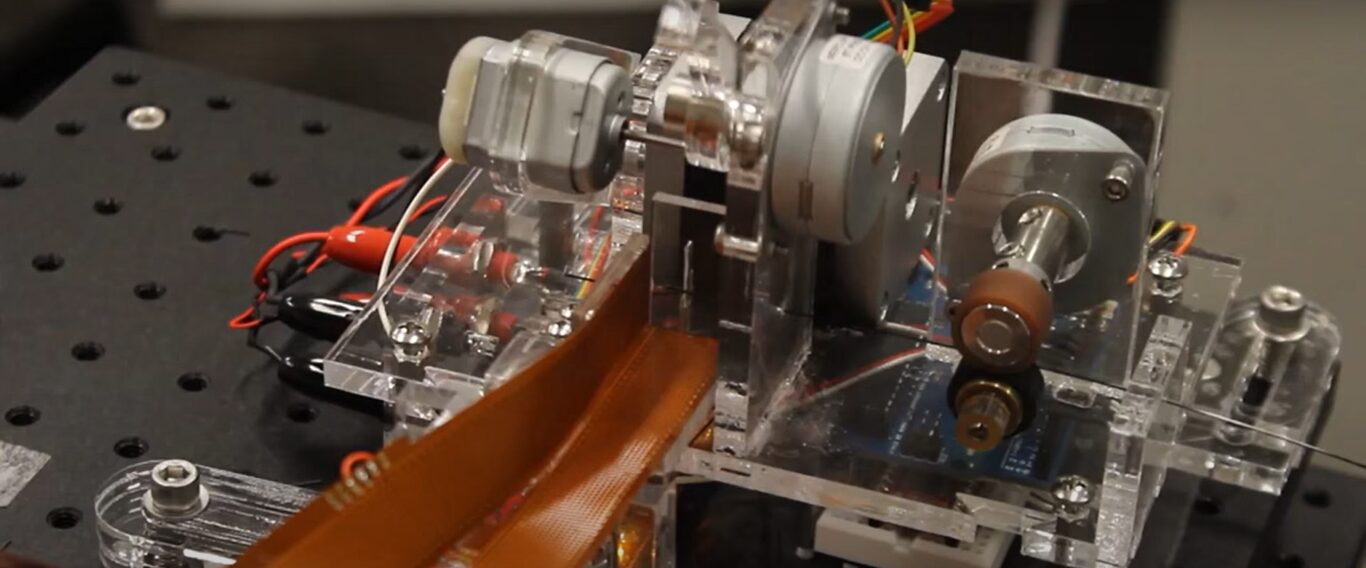

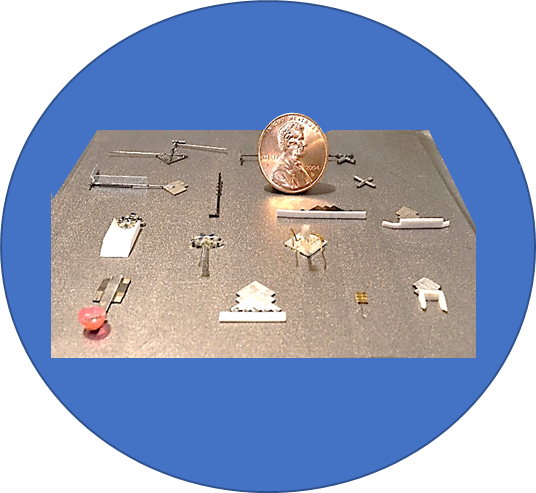

The diamagnetic micro factory is a complex system of local magnetic fields generated by a circuit board. A configurable software program manipulates the field to move miniature robots, which are themselves magnet arrays. Each individual robot is part of a collective…like ants in a colony…and every robot has a specialized task to perform. Tasks are performed by each robot’s end-effector, tools that can be used to manipulate any material. These robots can assemble almost anything…from massive to tiny. Compact systems of more than 1,000 micro robots have been assembled and demonstrated.

Pelrine Innovations is a research, design and development company focused on innovative automation using novel materials and new technologies. We believe that cutting edge technologies and novel materials can reinvent the world. We also believe that the value of a technology lies in its practical application and its ability to foster new and diverse development…which is why we are pleased to introduce the Diamagnetic Micro Factory…a platform designed to transform automation.

The diamagnetic micro factory system is a platform technology that can support applications across a range of industries as well as non-manufacturing processes. Through Pelrine Innovations, you can purchase a working beta level diamagnetic micro factory platform, activate your system, and customize it to meet your unique business and research needs. Join a community of like-minded researchers and developers focused on paradigm shifting solutions to business operations.

The diamagnetic micro factory is a complex system of local magnetic fields generated by a circuit board. A configurable software program manipulates the field to move miniature robots, which are themselves magnet arrays. Each individual robot is part of a collective…like ants in a colony…and every robot has a specialized task to perform. Tasks are performed by each robot’s end-effector, tools that can be used to manipulate any material. These robots can assemble almost anything…from massive to tiny. Compact systems of more than 1,000 micro robots have been assembled and demonstrated.

BUY OR BUILD? Consider using the turnkey diamagnetic microfactory as a platform for your research applications development. It can enable rapid prototyping, is easily customized, and reconfigurable…at a starting cost of less than $3000, the microfactory can accelerate development.

*patent pending

CAPABILITIES

manipulate any material

Micro factory robots can manipulate and deposit any substance…solid, liquid, powder, or paste.

heterogeneous fabrication

The Micro factory platform enables heterogeneous fabrication at the micro level, enabling different materials to be combined into a single structure.

swarming ability

Swarm and multi-agent integration and dynamics can provide coordinated and massive parallelism.

long distance transport and integration

Micro factory platforms provide long distance transport and integration across multiple devices and systems, enabling warehouse and storage libraries.

diamagnetic levitation

Diamagnetic levitation enables high speed, zero wear, and frictionless movement. Zero friction and wear allows robots to operate with electronic reliability at the micro level

biomimetic living systems

Micro factory robots are adaptive, self-replicating, healing, biomematic “living” systems at a micro level.

Advantages

Low power requirements

High speed operations

Scalable – tiny to massive

Configurable and easily customized

Modular

High precision

Frictionless with zero wear

Highly reliable

Applicable to multiple industries

Uses commercially available printed circuit board technology

Can integrate with 3D printer

Can integrate with machine vision

Endless array of end-effector options

Self-assembly capabilities

Cooperative robot operations

CAPABILITIES

manipulate any material

Micro factory robots can manipulate and deposit any substance…solid, liquid, powder, or paste.

heterogeneous fabrication

The Micro factory platform enables heterogeneous fabrication at the micro level, enabling different materials to be combined into a single structure.

swarming ability

Swarm and multi-agent integration and dynamics can provide coordinated and massive parallelism.

long distance transport and integration

Micro factory platforms provide long distance transport and integration across multiple devices and systems, enabling warehouse and storage libraries.

diamagnetic levitation

Diamagnetic levitation enables high speed, zero wear, and frictionless movement. Zero friction and wear allows robots to operate with electronic reliability at the micro level

biomimetic living systems

Micro factory robots are adaptive, self-replicating, healing, biomematic “living” systems at a micro level.

Advantages

Low power requirements

High speed operations

Scalable – tiny to massive

Configurable and easily customized

Modular

High precision

Frictionless with zero wear

Highly reliable

Applicable to multiple industries

Uses commercially available printed circuit board technology

Can integrate with 3D printer

Can integrate with machine vision

Endless array of end-effector options

Self-assembly capabilities

Cooperative robot operations

PUTTING IT ALL TOGETHER

View actuated diamagnetic micro-robots performing advanced manufacturing functions