Advancing New Technologies through Innovative Research, Design, and Development

Tomorrow’s Innovations Delivered Today

Imagine…

An automated railway system operating on the moon…levitated objects without power cords…programmable micro-robotic sensors that automatically learn, evolve and replicate…wall climbing robots…changeable wall patterns… clothes that turn into armor…lightweight carbon structures strong enough to support elevators to space…. frictionless rubber combustion engines… paradigm shifting concepts that improve life through new technologies and materials.

Pelrine Innovations is a research, design and development company focused on innovative automation using novel materials and new technologies, including diamagnetic levitation, dielectric elastomers, electroadhesion, polymer design and micro robotics. We seek to re-imagine business processes through contract research and the development of micro factory systems.

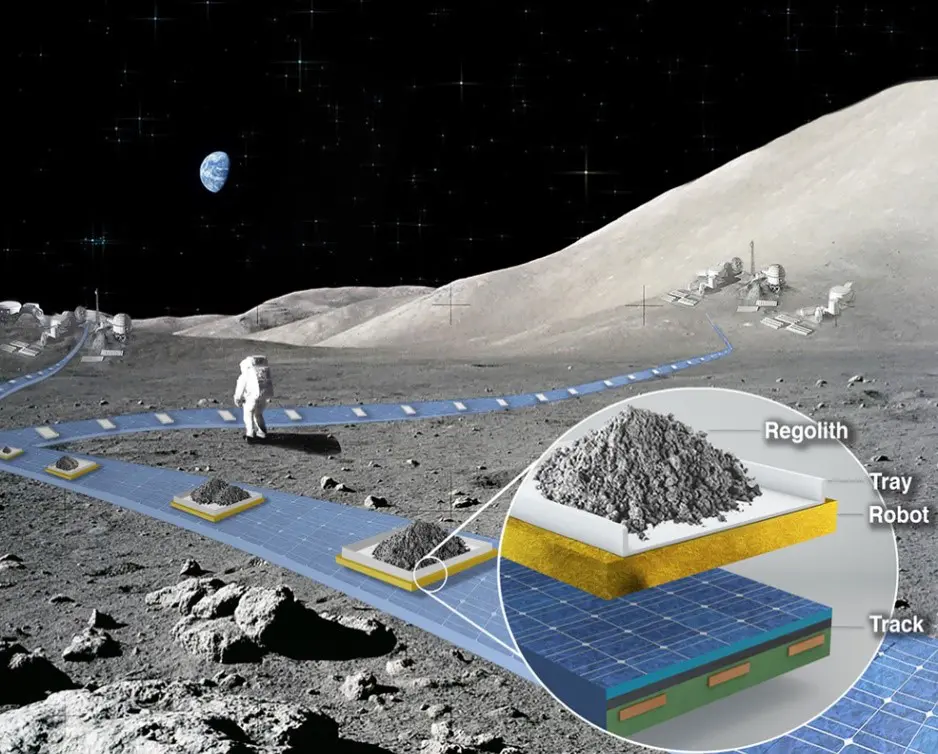

Railway Systems on the Moon

It’s called FLOAT, short for Flexible Levitation on a Track…a concept showcased at the 2021 NASA Innovative Advanced Concepts Symposium. FLOAT consists of unpowered magnetic robots that levitate over a 3-layer flexible track, unrolled directly onto the lunar surface, requiring minimal preparation, thus avoiding major on-site construction.

Thin film solar panels generate power, while the track’s graphite layer enables the robots to float over the tracks using diamagnetic levitation. The flex circuit layer generates electromagnetic fields to controllably propel robots along the tracks.

Because the robots have no internal moving parts, they can support payload delivery from point to point, while levitated transport allows them to avoid contamination and transport delays

Due to moon dust.

Artist’s depiction of the FLOAT lunar railway. Credit:NASA/JPLCaltech

Imagine a rope stretched vertically between the equator and a geostationary orbit. A little beyond this orbit, the rope would be attached to a large mass, for example an asteroid, so that the equilibrium point of the complete structure is precisely in the geostationary orbit.

The system is theoretically stable and does not need energy to maintain itself. Carbon nano tubes, which have the potential to be 100 times stronger than steel yet flexible as plastic, make this concept feasible.

Previously available materials were either too weak or inflexible to form the ribbon and would have been easily broken.

CREDIT: Space Elevator In Clouds by Liftport [GFDL (http://www.gnu.org/copyleft/fdl.html) or CC-BY-SA-3.0 (http://creativecommons.org/licenses/by-sa/3.0/)], from Wikimedia Common

Elevator to Space

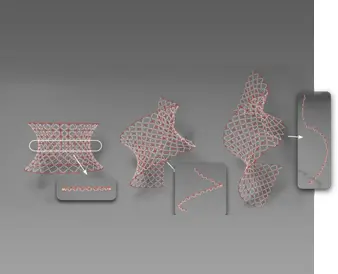

Shape Shifting Materials

Imagine if you could bend your phone and turn it into a watch. Or if your desk could morph into a chair. Or if, when using FaceTime or Skype, you could not only see and hear the other person, but also feel him, too. And instead of needing a coat for each season, imagine a jacket that dynamically changes shape so it becomes more insulating to keep you warm as the temperature drops. Dielectric elastomers, electroadhesion, and electrolaminates are some of the technologies that can create shape shifting materials.

Sean Follmer, a computer researcher and designer at the MIT Media Lab and his team constructed a surface that lies flat in front of the user. It displays text, figures, and other information, and the user interacts with it much as he would an iPad. And that's where things get funky: As you manipulate the flat surface, hundreds of small pins push upward to different heights. The interface takes on the three-dimensional form of whatever you are looking at, be it a pie chart or an urban landscape--like a high-tech raised-relief map.

Credits: MIT's Tangible Media Group and Liz Stinson, Wired Design, 5/25/16

It’s called IN-DEEP, a process designed to harvest and distribute wave energy through a system of multiple harvesting cells, comprised of a novel dielectric elastomer metamaterial. Through mechanical and electrical connections, the cells work together to produce power. A successful wave power system must be low-cost and above all, reliable, an objective difficult to achieve with traditionally manufactured dielectric elastomers.

The metamaterial cells at the basis of this design are created through novel manufacturing methods designed to deliver innovative dielectric transducers. Well-matched to wave power frequencies, stroke, and cost effectiveness coupled with an innovative manufacturing approach based on DM3 technology, the energy harvesting process includes massive parallel assembly of all components, including electronics, reducing cost and time, and the ability to “pre-screen” individual elements, increasing reliability.

Credits: Harvard Seas (Harvard John A).

Harvesting Energy from Waves